Celebrate and share when prints go wrong and blow up. Take notes, take photos.

Bed adhesion / print not sticking to bed

Brain dump notes to a fellow T3r struggling with Dread Spaghetti.

Sanity check the bed surface:

-

Clean / wipe down build plate

no oils - human fingers are greasy even when we don't think they are -

Add some of the glue stick or blue tape to the print bed

-

Run the calibration tool again.

Level the bed, Fix Z-Offset -

Change out the build plate to different style.

-

Print a Benchy to give yourself a warm fuzzy about fundamentals

-

keep a log / notes of settings and where things are going sideways and how (pictures help) so you can try and spot any patters. That is the top of head list (things I've been having to do last few days)

Ohh, and one thing I realized I did that in retrospect should probably be normal habit -- print a Benchy for each filament you have in the AMS -- that lets you sanity check a few things AMS feed / filament itself / othe aspects of the whole system - especially if you pay attention and move the various benchy's around to different quadrants of the print plate.

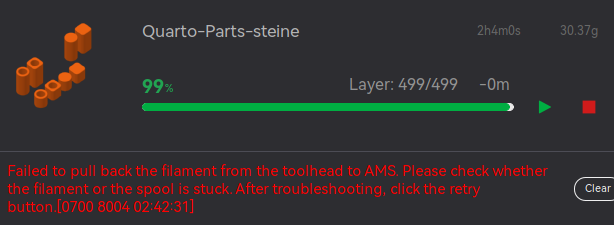

Failed to pull back the filament

Failed to pull back the filament from the toolhead to AMS. Please check whether the filament or the spool is stuck. After troubleshooting, click the retry button. [0700 8004]

- Bambu Lab Wiki - Troubleshooting - Cannot pull back the filiment

- Possible Causes:

Filament end expansion, Spool stuck, AMS filament inlet or outlet issue, stuck extruder filament sensor - Suggestions:

- Check if the filament end expansion. If yes, cut expansion parts and try again.

- Check if the filament on the spool is spreading. Spreading means that the speed is too slow or the filament is stuck. It may be the hardware filament inlet or outlet components are abnormal and need to be repaired or replaced.

- Provide log to official customer service to roughly judge the area where the filament is stuck.

- Possible Causes:

- Reddit/BambuLab/Help AMS failing to pull back filiment

- "Could it be that the spools are cardboard spools? If so, BL recommends not to use those in the AMS. ... Be careful as this could mean dust from the cardboard could have entered inside the AMS gears, and it could fail again. If it happens again, make sure to look for ways to clean the gears of dust. ... print the cardboard adapters" - Unapedra

- Power cycle the printer.

- "When it fails, I disconnect the PTFE tube on the back. The filament easily pulls out of the extruder. From there, hitting RETRY works. Just be sure to reconnect the PTFE tube before the next filament feeds in." - SR22pilot2

- "I've narrowed mine down to the buffer spring getting stuck/angled in such a way that the Filament is unable to retract. Release the tension on the spring and it retracts perfectly." -lumenknife

- "I’ve had this happen a few times, and my only resolution was clipping the filament and taking the spool out of the AMS, disconnecting the PTFE on the back of the unit and the pull it out by hand." - Dtjb821

- Bambu Lab X1 PTFE Minimum Radius Guide